We have also addressed this we hope in the upcoming release as I too have seen this a lot - part of the issue is that on Templates there are settings that get partially controlled by classification of the surfaces - so when you use a Surface Instruction for Design and another for subgrade both surfaces need to be either classified the same way or they both need to be set up also as reference Surfaces in the corridor - that way you can get at the controlling settings that are shown here (click lines by the TIN models on the reference surface in the Template Editor to access the Properties

The Adjust for Arc to Chord setting gets applied differently for Design Surfaces to other surfaces - this adjusts the positions of the nodes in the cross sections to account for the chording of the lines in the model caused by the TIN model, and adjusts them based on the curvature of the alignment at that station - on the outside of the curve this pushes the nodes away from the Centerline, and on the inside of the curve pulls the nodes closer to the centerline, if you look at a station where the design data was computed - most of the time everything looks good, however move to somewhere between the sections from the design data and you get the Default Subgrades - this can cause the issues that you are seeing - if one surface instruction is a Design Classification and another is not, then the default behavior for one surface is to have this setting set to Yes (the Design Surface) and the other to No (the Non Design Surface). When this happens, where two surfaces should tie, they actually miss or cannot find a vertical tie because one node is adjusted and the other is not - this will often affect you along the edges of a Design model as shown below

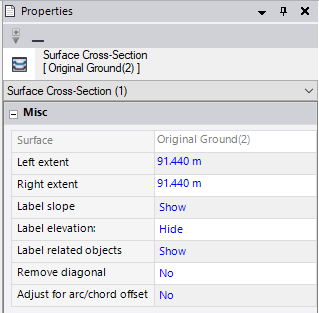

The Red Line is the Finished Grade and is set to Design Classification and has the Adjust for Arc / chourd offset set to Yes

The Brown Surface is a Topsoil Replacement layer (base of) and that is a surface instruction set to Unclassified and therefore has the Adjust for Arc / chord offset set to No.

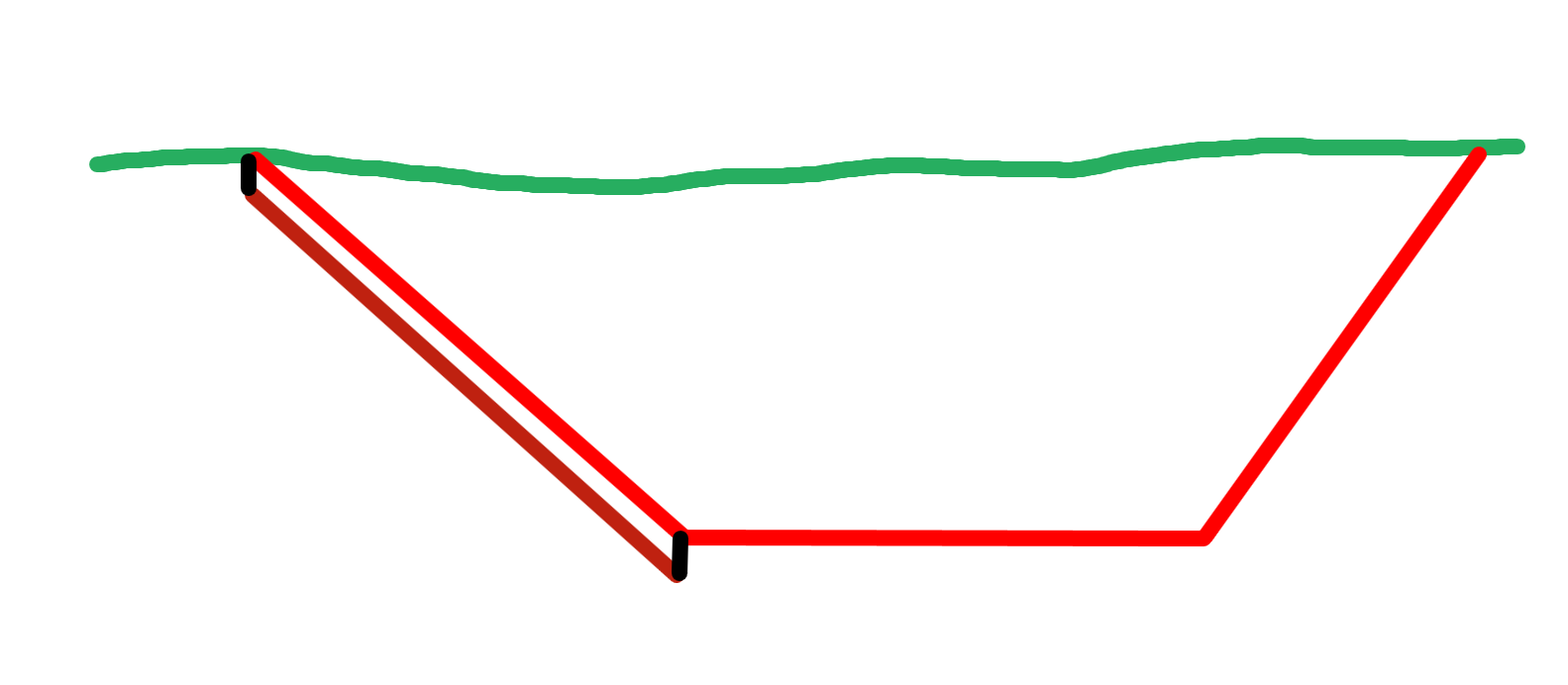

When Arc to chord is set to Yes this is what happens

The TIN Model along the grey station section line shows the point to be at AA (this is the unadjusted position), and if the Arc/Chord offset adjustment is set to Yes then the node AA is moved mathematically to position BB. On the inside of the curve the movement is toward the centerline. so if one surface moves the node, yet the other surface does not, then the two nodes are no longer in exactly the same place, which can leave a gap that can cause failure to tie up to the surface above (leaving no material fill in the template editor) or can leave a gap through which materials can flood and that can cause either the wrong material or Default Subgrade (because 2 or more materials are defined in the same area of the section.

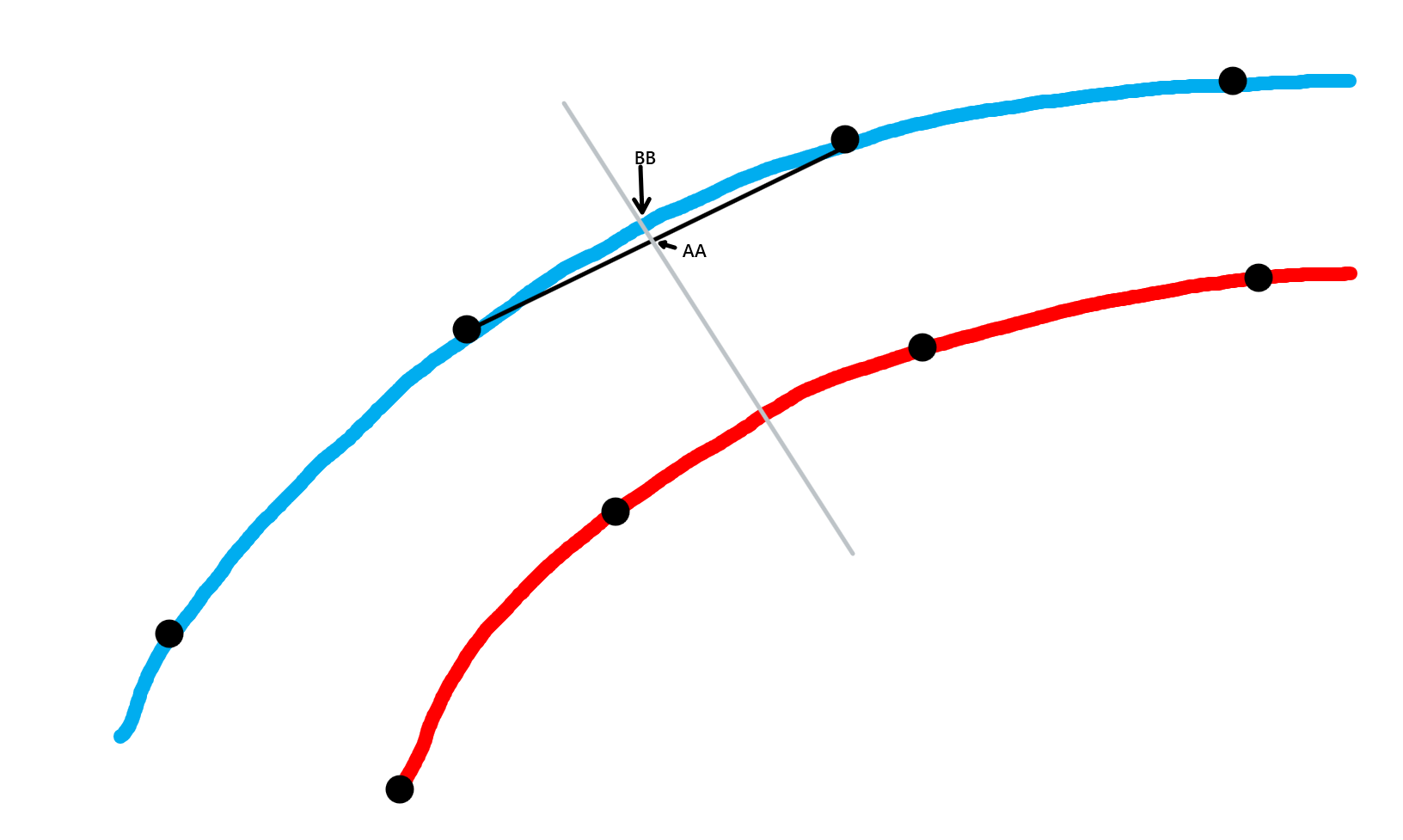

So set the surfaces for the Design and Subgrades to have the same settings here and also for the Remove Diagonal (which really only applies to Design Surfaces and Design Subgrades) to eliminate the warping effect that can happen between two source strings in a Surface Model where the elevations create two alternative surfaces as shown below

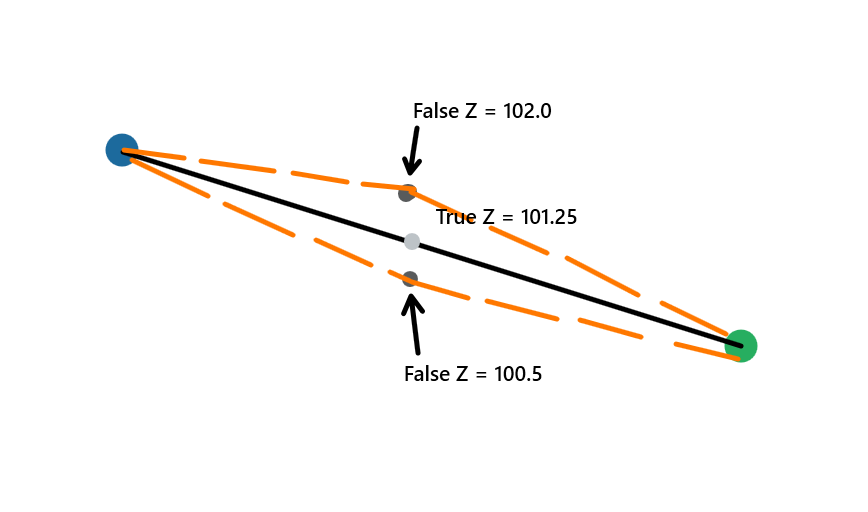

The surface is created from2 strings (the Blue and the Green lines). At the location indicated by the Grey Section line we are slicing the surface model TIN. At this location we would have the point at which the section crosses the two strings (the Blue Dots) and also a point where the section crosses the TIN side between either points 1 and 4 or 3 and 2. The slope between the two strings gives an elevation at the mid point of 101.25, however the two TIN options give elevations of 102 or 100.5 (both of which are incorrect in this scenario (this is one of the known issues using TIN models). So in a corridor model we know things are computed perpendicular to the centerline, and we know that the strings typically indicate the start and end of a linear slope - so we can basically ignore the "diagonal" and just use the strings to define the surface instruction, thereby eliminating the errors caused by the TIN side interpolation. This can improve the section as shown below

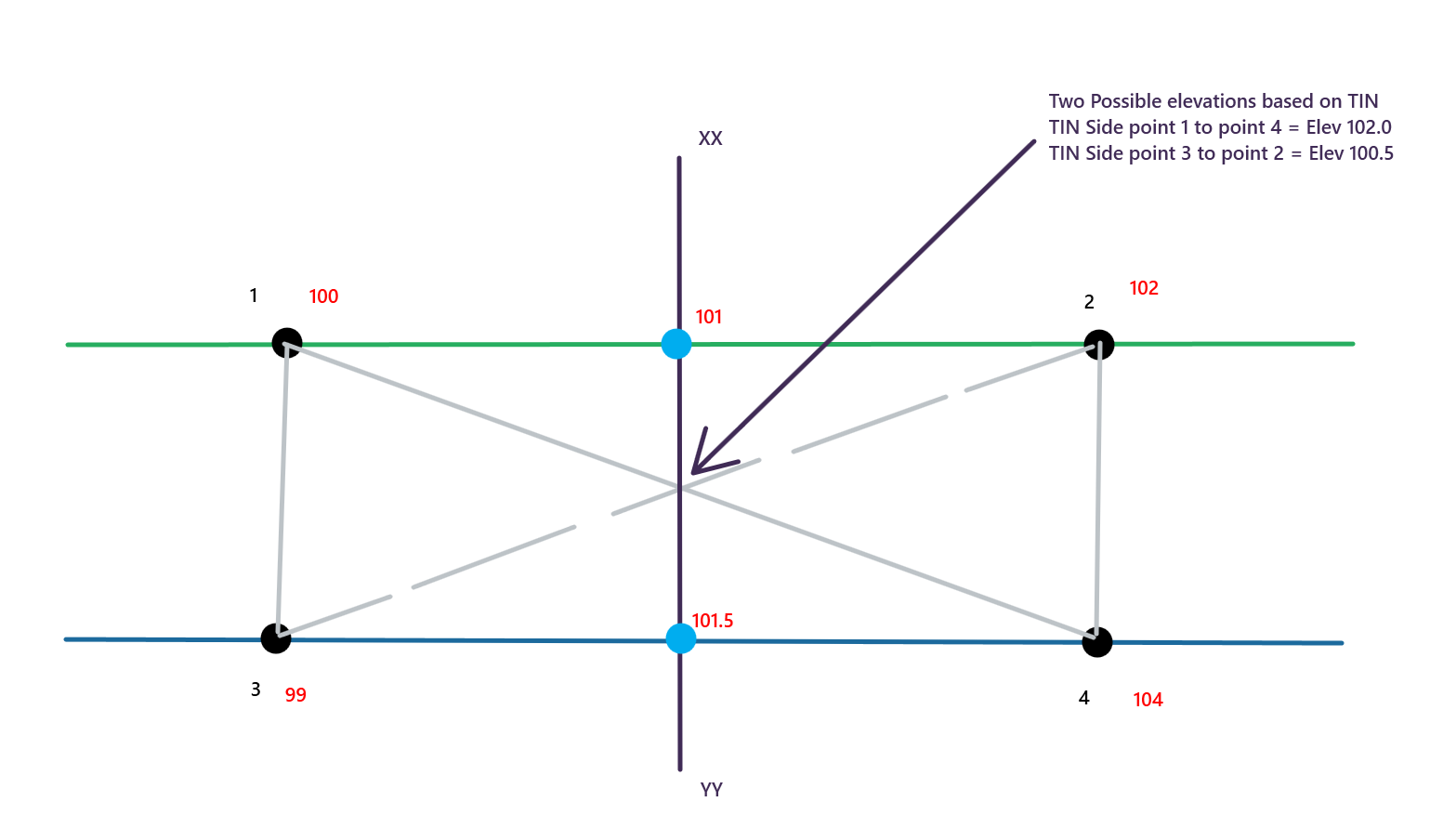

If you did not apply the remove diagonal then you would get one of the two orange surfaces at the indicated location between the two strings. If you apply the remove diagonal then you will get the black line between the two strings and the right answer for the surface. This really only applies to Design Surface models that have been constructed from 3D strings interpreted from a corridor like model (similar to that of TBC e.g. Civil 3D, OpenRoads Designer, 12D etc.)

When you see the Default Subgrade or No Material defined, then this should trigger the research into the above issues and trying to solve by fixing the problem in the data / model.

Hopefully this helps to explain the issues you are seeing - you have to put them into your own context, but these are the most common issues and causes.

Alan